Special Tools

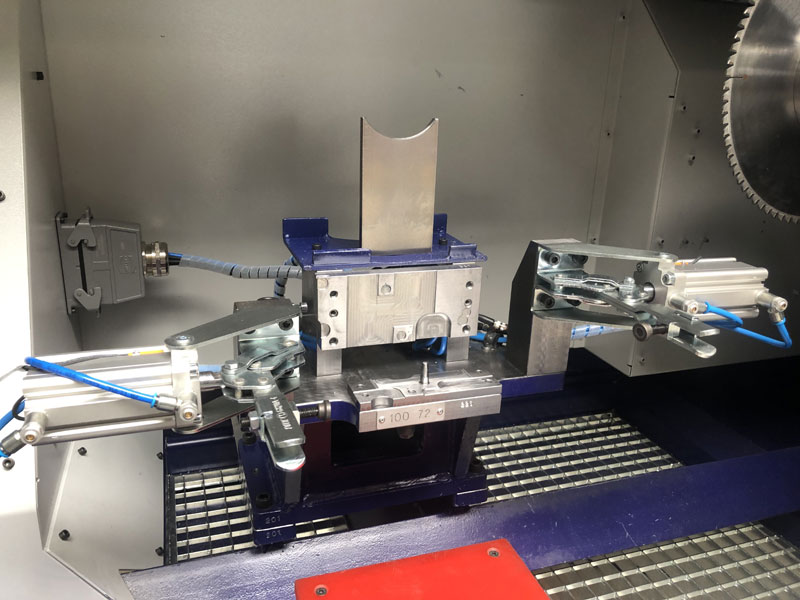

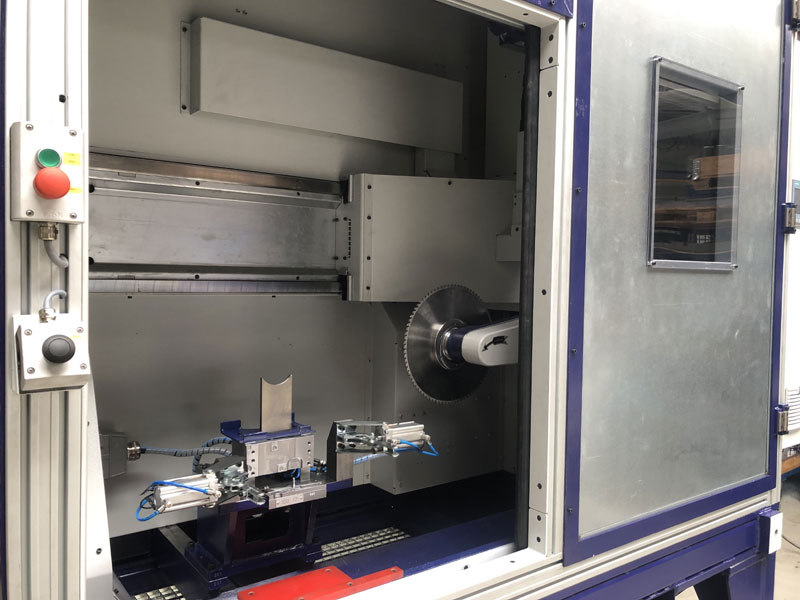

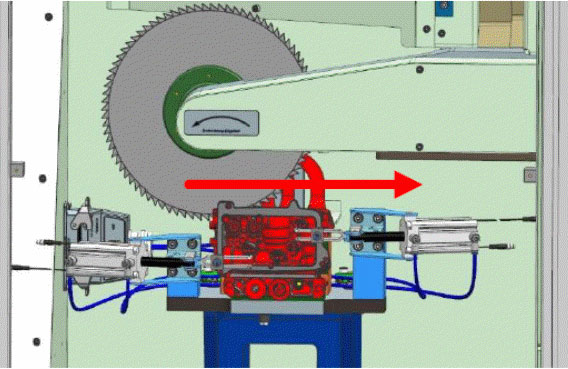

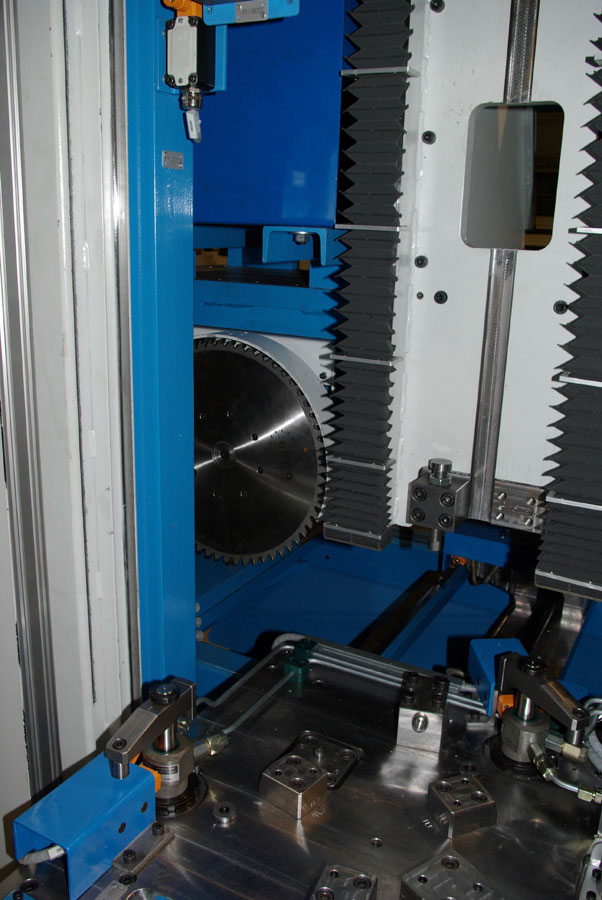

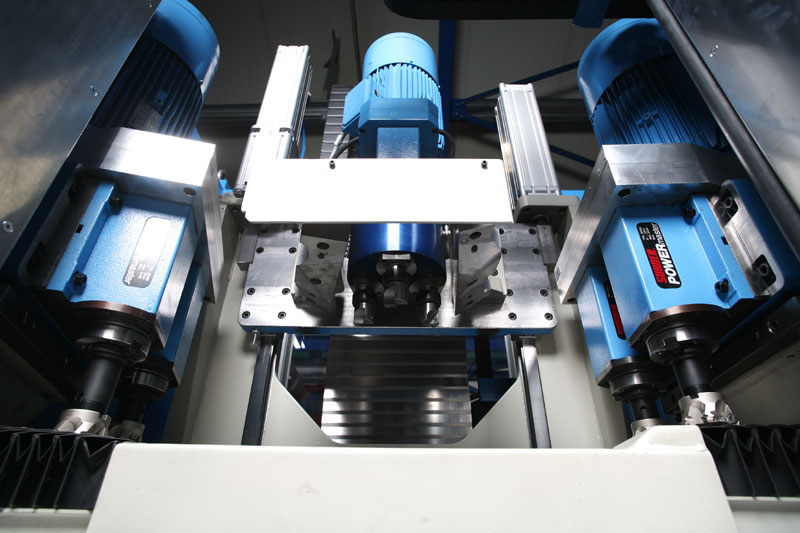

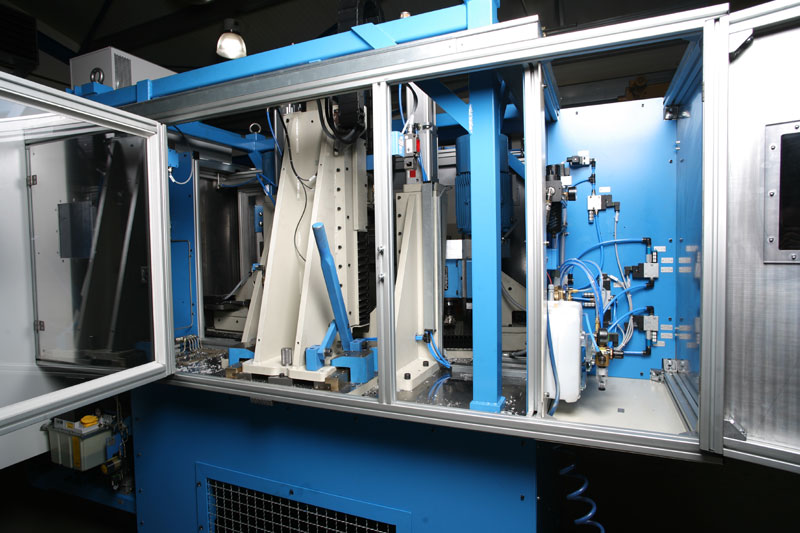

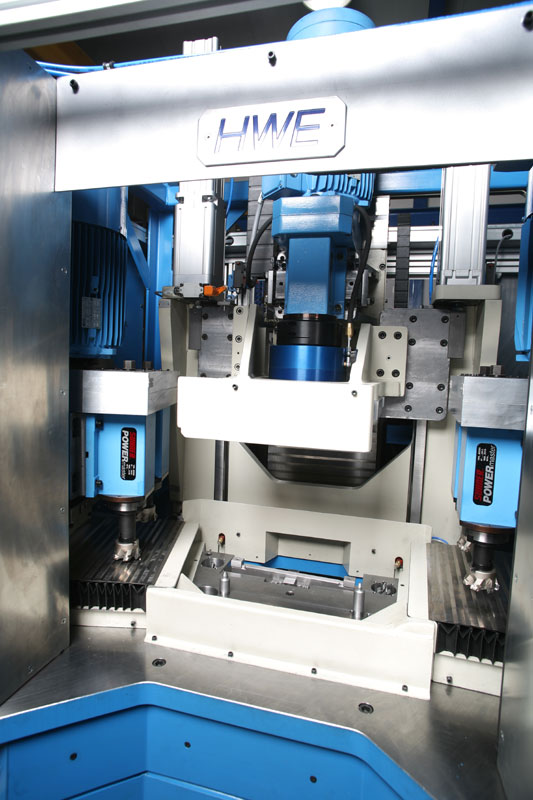

Universal saw

With interchangeable sets for different castings for large and small batches

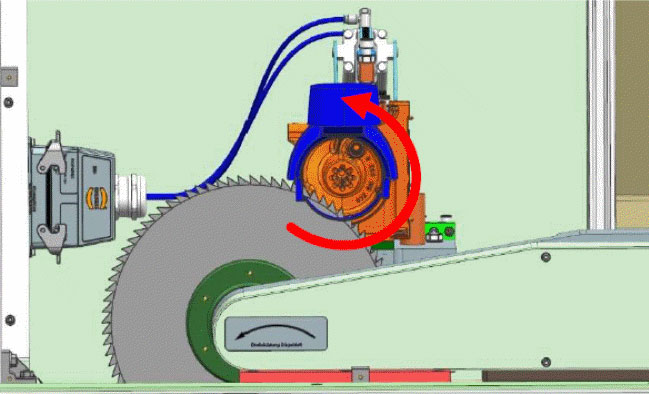

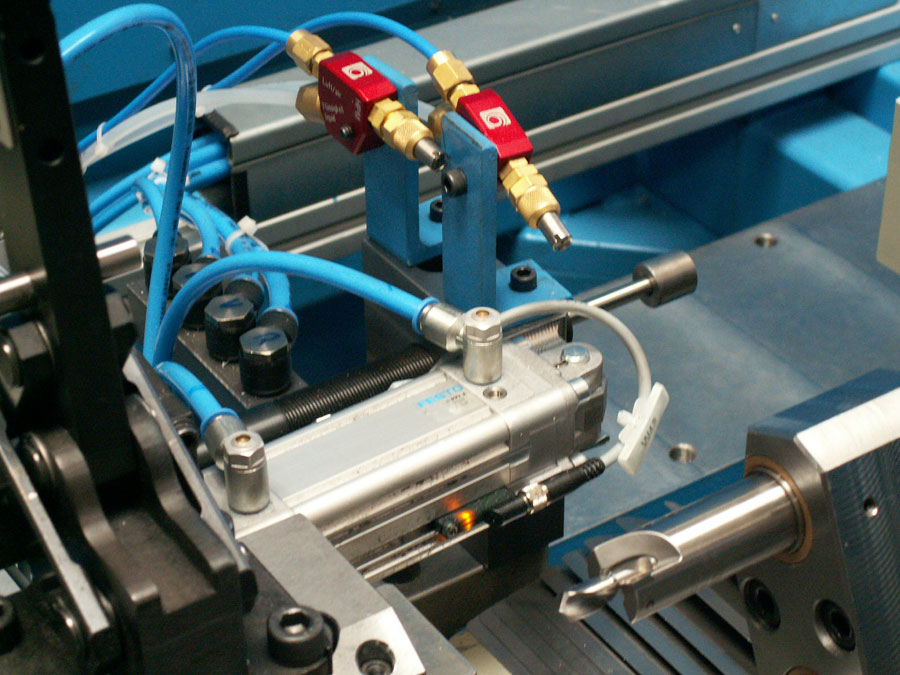

Sawing functions

- Sawing of "problem parts" (e.g. ring sprue)

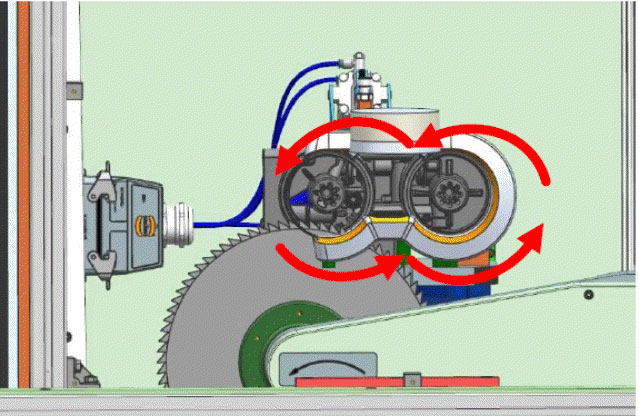

- Sawing of curved paths (protruding centre pin on the casting)

- Sawing of curved paths (protruding centre pin on the casting)

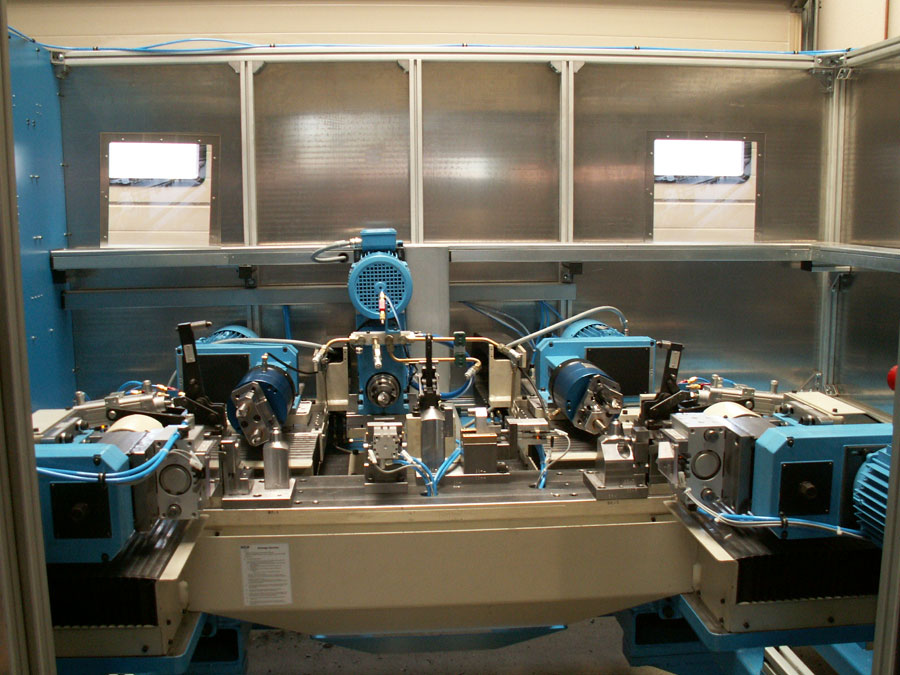

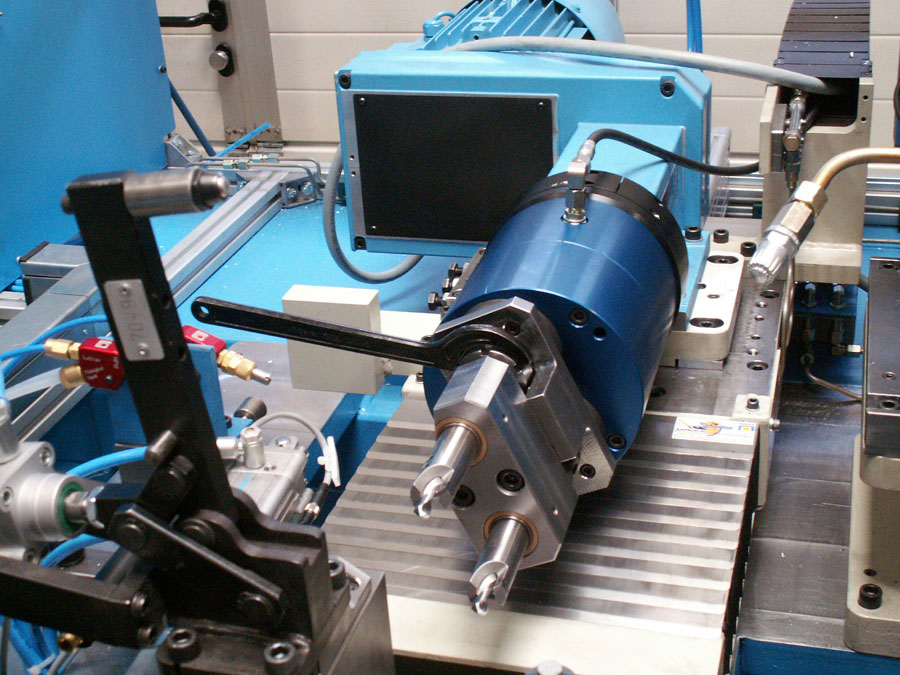

Clutch Housing

Sprue sawing and drilling on the part in one operation